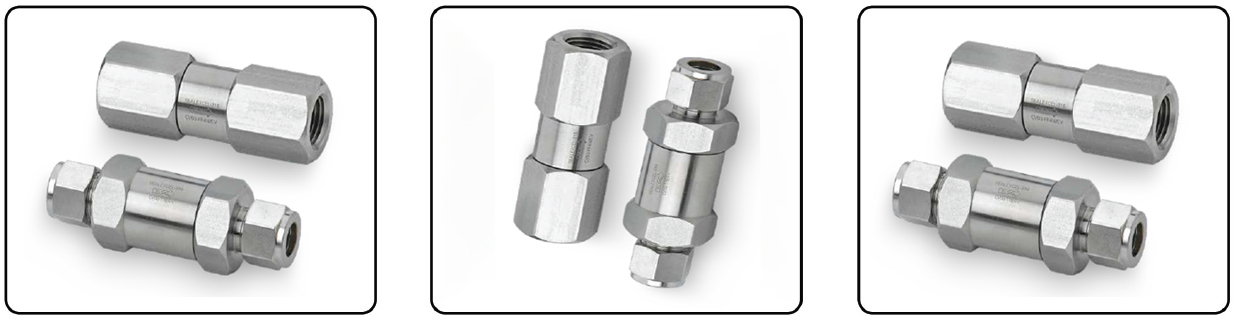

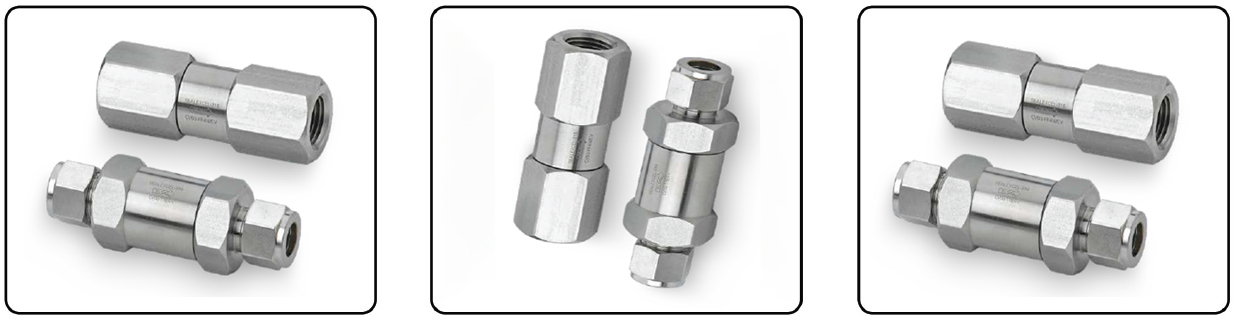

Check Valves

Product Enquiry

Product Enquiry Check Valves

Check ValvesCheck valves are used to restrict the flow in only one preferred direction.

It provide unidirectional flow and tight shut off in the other director for liquid and gases.

The check valve opens when the differential pressure is more than the cracking pressure and media will flow in preferred direction, while when the differential pressure is below cracking pressure, the valve will close thereby no media will flow.

Important Features of Check Valves

Important Features of Check Valves

Material can be SS316, SS304, Monel, Hastelloy and others. Complete Material traceability to its Material test report is available.

Material can be SS316, SS304, Monel, Hastelloy and others. Complete Material traceability to its Material test report is available.

All wetted parts can be offered as per NACE MR-01-75

All wetted parts can be offered as per NACE MR-01-75

Design Pressure: 205 barg / 3000 psi & Temperature: upto 200??C

Design Pressure: 205 barg / 3000 psi & Temperature: upto 200??C

Sizes are from 1/8" to 1".

Sizes are from 1/8" to 1".

Cracking pressure shall be from 1 psi to 25 psi.

Cracking pressure shall be from 1 psi to 25 psi.

Available in all possible configuration of end connection.

Available in all possible configuration of end connection.

Industries

Industries| Oil & Gas Industry |

|

|---|---|

| Process Industry | |

| Power Industry | |

| Refinery & Petrochemical Industry | |

| Chemical Industry |

Check valves are generally installed in pipelines to prevent backflow. A check valve is basically a one-way valve, in which the flow can run freely one way, but if the flow turns the valve will close to protect the piping, other valves, pumps etc.

Check valves are generally installed in pipelines to prevent backflow. A check valve is basically a one-way valve, in which the flow can run freely one way, but if the flow turns the valve will close to protect the piping, other valves, pumps etc.

We are the leading Manufacturer / Exporter / Supplier of Check Valves in India and Overseas.